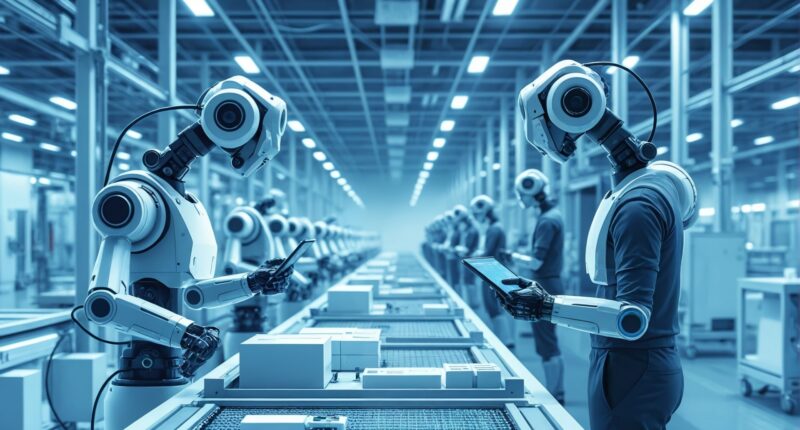

In today’s fast-evolving industrial world, robotics has become one of the most powerful forces shaping the future of manufacturing. Modern robots are not just about automation — they are about precision, speed, and efficiency. By integrating robotics with artificial intelligence (AI), companies can streamline production, reduce costs, and achieve higher quality outcomes.

The Rise of Robotics in Manufacturing

The manufacturing industry has witnessed a massive transformation over the past few decades. From simple mechanical arms to advanced, AI-driven systems, robots have taken center stage in the industrial revolution. Today, they are used for welding, assembly, packaging, material handling, and even quality inspection. This rise of automation has not only increased productivity but also allowed businesses to operate around the clock with minimal human intervention.

Automation and Efficiency

One of the key benefits of robotics in manufacturing is improved efficiency. Robots can perform repetitive tasks faster and more accurately than humans, reducing the risk of errors. This consistency leads to higher output levels and better product quality. Additionally, automation minimizes downtime and increases flexibility in production lines, allowing manufacturers to meet market demands more quickly.

Safety and Workforce Impact

Another significant advantage is safety. Robots can handle dangerous tasks that would otherwise put human workers at risk. For example, in automotive or chemical industries, robots can perform welding or material handling in hazardous environments. While there are concerns about robots replacing human jobs, many companies are finding a balance by upskilling employees to work alongside machines in supervisory or maintenance roles.

Technologies Driving Robotic Transformation

Recent innovations in machine learning, computer vision, and IoT (Internet of Things) have enhanced the capabilities of industrial robots. Collaborative robots, or “cobots,” are now designed to safely work alongside humans, adapting to their movements and assisting in real-time. This human-robot collaboration makes production faster, safer, and more adaptive to changes in demand.

Smart Factories and Data Integration

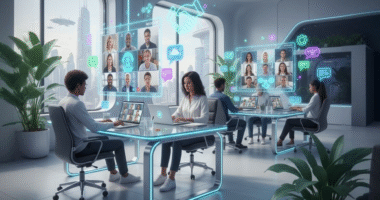

Smart factories are the next step in robotic manufacturing evolution. By connecting robots to cloud-based systems, data analytics tools can monitor performance, detect faults, and optimize operations instantly. This integration leads to predictive maintenance, reducing downtime and improving overall equipment efficiency (OEE).

The Future of Robotics in Manufacturing

As technology continues to evolve, robotics will become even more integral to manufacturing. With AI-driven decision-making, real-time monitoring, and self-learning capabilities, the factories of the future will operate with minimal human oversight while maintaining high efficiency. Companies investing in robotic systems today are setting themselves up for long-term success and sustainability.

Conclusion

Robots are no longer a futuristic concept — they are the present and future of modern manufacturing. By embracing robotics, businesses can ensure productivity, safety, and competitiveness in an ever-changing industrial landscape. The transformation may be ongoing, but one thing is clear: robots are here to stay, and they are redefining how we create and build in the modern world.